Lupus Engineering Services Ltd

Specialists in Marine Renewable Energy

Triton

In 2006 we worked with Triton Submarines, based in the USA, on the analysis of their Triton 1000/2 model.

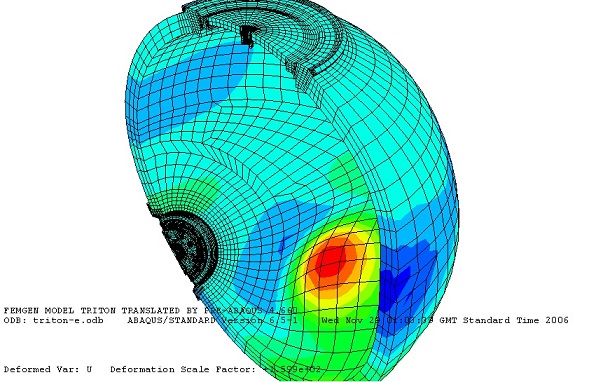

The work included analysis of the main acryllic sphere and hatch sealing system, employing non-linear contact analysis to discern the collpase dive pressure for demonstrating code compliance.

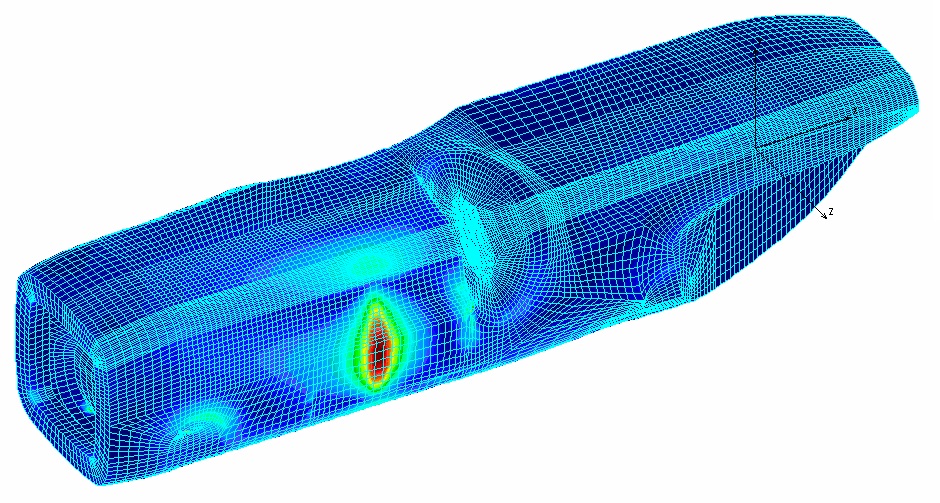

Further work was undertaken on the composite ballast tanks to determine their resistance to side impact loads.

Images below are reproduced with the kind permission of Triton Submarines.

In 2006 we worked with Triton Submarines, based in the USA, on the analysis of their Triton 1000/2 model.

The work included analysis of the main acryllic sphere and hatch sealing system, employing non-linear contact analysis to discern the collpase dive pressure for demonstrating code compliance.

Further work was undertaken on the composite ballast tanks to determine their resistance to side impact loads.

Images below are reproduced with the kind permission of Triton Submarines.

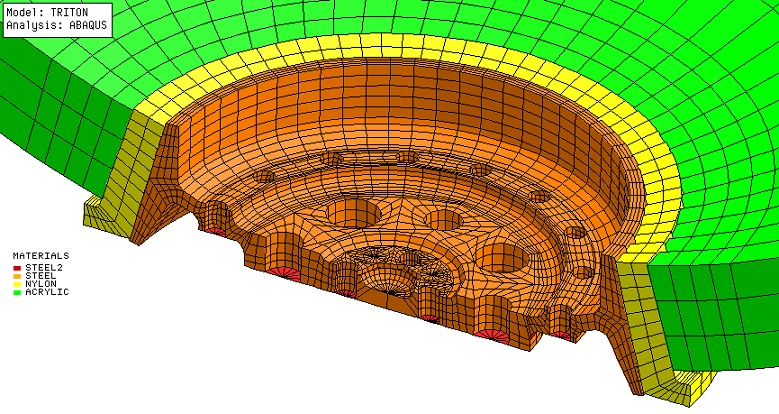

Triton Assembly

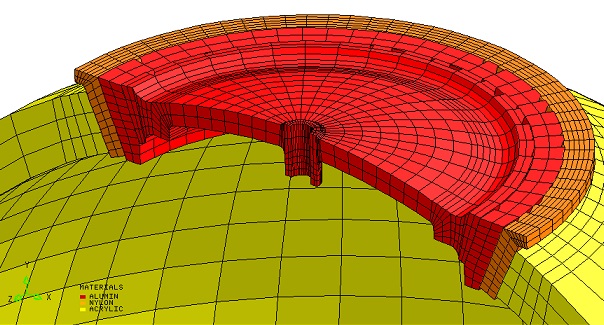

Upper Hatch Assembly

Lower Penetration Blank Assembly

Sphere Assembly - Eigen Mode 1 used for imperfection seeding

Displacements from Ballast Tank Impact